A Week on the Estate: New Leather, Old Skills & Craft Renaissance

Meteorological winter is well and truly here. The solstice is barely three weeks away and the coming week is set to bring us highs of 7C, lows of -1C and a possibility of sleety showers over the weekend. If you’re joining us for the last weekend of our Autumn Tours programme, do make sure you dress for the weather.

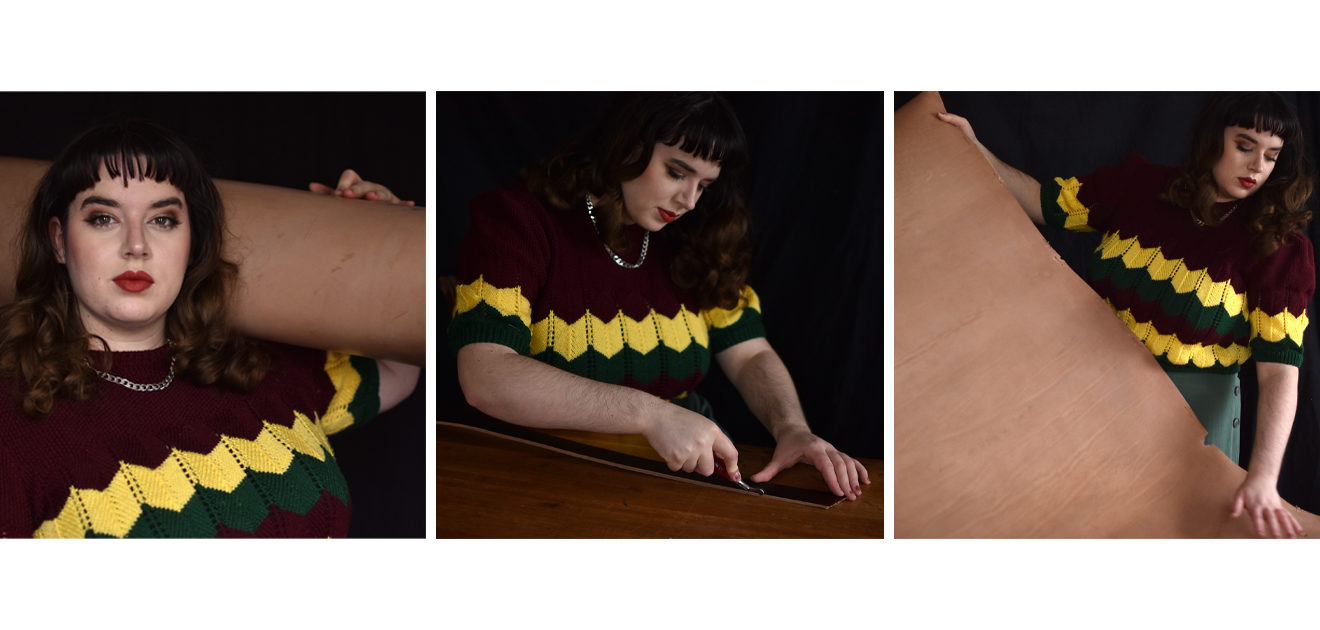

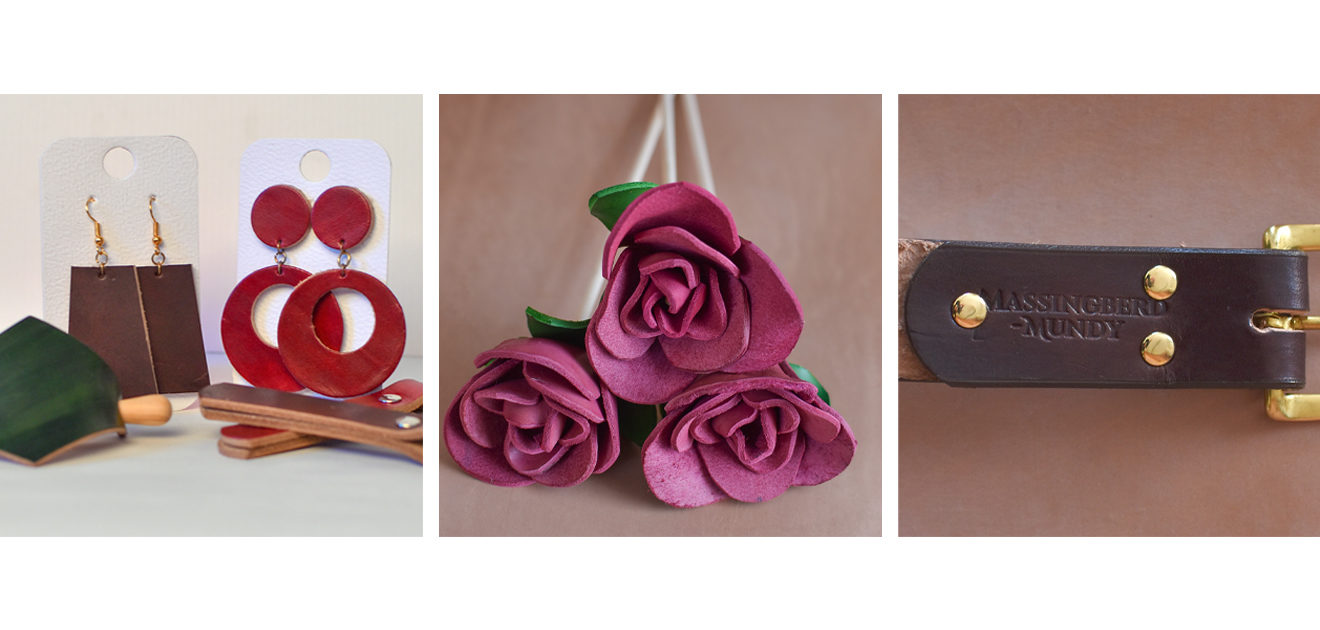

Last week, we proudly announced our brand-new range of Massingberd-Mundy Luxury Leather Goods, celebrating local craftsmanship and the fifth quarter of our rare-breed, grass-fed Lincoln Red cattle. This week, we’re digging a little deeper into the craft of leather-making with the help of our very own Finn Bracey.

“When I was project officer on the beef operation, a large part of the job was finding ways to use the significant part of the animal that isn’t edible,” said Finn. “The fifth quarter is substantial, with things like bones, fat and, of course, the hide.

“The skin isn’t the heaviest part. It’s an insignificant proportion of the overall weight of the animal but finished leather is clearly useful. We were keen to reduce waste and gain more commercial value from the beef operation.

“The first step was to find a way to get the hides tanned. It seemed simple but wasn’t. There are very few tanners left in the UK due to lack of demand. Tanning tends to be outsourced abroad. We also wanted a tannery that did vegetable rather than chrome tanning.

“Vegetable tanning is more traditional and environmentally friendly and fits with our sustainable approach. It’s also slower, using bark and taking up to a year. Chrome tanning by contrast is quicker but uses more synthetic chemicals.

“Our relatively small scale was also an issue. We’re sending modest numbers of hides to the tannery by industry standards. It’s normal for tanneries to process large batches through several baths, but we needed them to keep ours traceable. We went with Spire Leather of Chesterfield. Their tannery has been around since the mid-19th century; they understood what we wanted and were happy to help.

“Our Lincoln Red leather is smooth, soft and beautiful with an authentic appearance compared to other high-grade varieties. Our Reds live outdoors all-year round and their stories are written on their skins. There are fine veins, as well as knots and scrapes from scratching on trees and thorny hedges.

“I’ve been training in leather-making for just over a year. Having practised on bought-in leather, I find ours superior and more of a pleasure to work with. I wondered at first if Spire had dyed it but I realised it has a natural, rich, biscuit-coloured finish.